The University of Science and Technology of China has developed a wearable adaptive penile hardness monitoring system, which can be used to assess erectile dysfunction!

Erectile dysfunction (ED) is a common sexual dysfunction, and continuous monitoring of spontaneous nocturnal erections and penile rigidity is crucial for its diagnosis and classification. However, current clinical standard devices, due to their limitations with active mechanical loading, are bulky, non-wearable, and strongly interfere with erections. This not only affects the reliability of monitoring but also reduces patient compliance.

Recently, Professor Pan Tingrui’s team from the University of Science and Technology of China developed a wearable adaptive rigidity monitoring (WARM) system. This system utilizes a measurement principle without active loading and evaluates penile erection and hardness using a specially designed elastic dual-ring sensor. The dual-ring sensor consists of two strain-sensing rings with different elastic moduli, providing high resolution (0.1%), robust mechanical and electrical stability (sustaining over 1,000 cycles), and strong interference resistance. An integrated flexible printed circuit (FPC) collects and processes the sensing signals, which are then transmitted to a host computer via Bluetooth for ED assessment.

Additionally, the system facilitates simultaneous sleep monitoring during nocturnal erection tests, continuously assessing penile rigidity while minimizing disruption to nocturnal erections. This system offers a fully integrated, wearable solution for continuous, accurate, and patient-friendly measurement of penile erection and hardness.

The research, titled “A wearable adaptive penile rigidity monitoring system for assessment of erectile dysfunction,” has been published in the latest issue of the Nature partner journal 《Microsystems & Nanoengineering》.

Principle of Penile Erection Rigidity Measurement and the WARM System

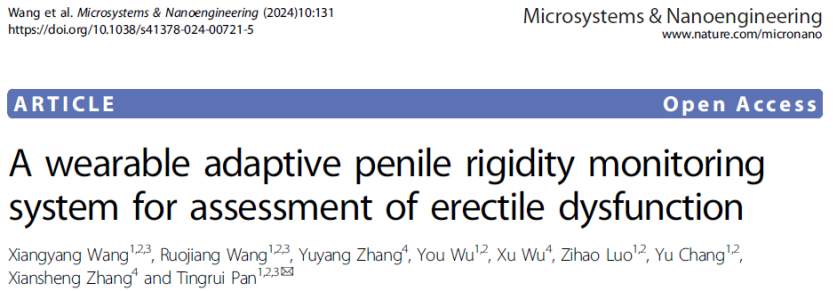

First, compare the working principle of the WARM system with the widely recognized clinical device, RigiScan. The principle of RigiScan for assessing penile erection and rigidity is based on dynamic mechanical measurement. Specifically, the erection is evaluated by the changes in penile circumference during erection, and the rigidity is evaluated by the ability to resist radial deformation under a known compressive force, as shown in Figure 1a. It can be observed that RigiScan applies tensile force in the tangential direction. This tangential stretch can then be converted into radial compression, thereby altering the radial shape of the penis, and the corresponding circumference is measured.

To implement such a measurement, RigiScan uses a two-step process. Initially, a gentle reference load (Tr) is applied periodically to measure the penile circumference (Dr) without causing significant deformation. When a significant change in penile circumference is detected, the RigiScan device can then apply a stronger compressive load (Tm) while continuously assessing the corresponding circumferential displacement (Dr-Dm), thereby determining the radial rigidity (S) as S = (Tm-Tr)/(Dr-Dm). As a result, the system design must include a motorized loading component with a high-precision length measurement unit, which increases the system’s complexity and limits its use in clinical settings.

Figure 1b illustrates the schematic of the WARM system, which is designed to monitor penile erections. The wearable sensor device provides real-time information on penile rigidity and erection, transmitting it instantly to a mobile device via a Bluetooth module, allowing doctors to conduct more accurate analyses and diagnoses. As shown in Figure 1c, the system consists of three main components: a precise and stable dual-ring sensor composed of two sensing units with different elastic moduli, namely the reference ring and the measuring ring. Specifically, the flexible dual-ring sensor, with different elastic moduli, can adaptively apply varying levels of load to the penis and convert the circumferential data into capacitive output. The sensor is reversibly connected to the FPC board via a standard connector, enabling the capacitive detection module to capture signals. Subsequently, the microcontroller unit (MCU) performs real-time evaluation of penile rigidity and erection.

Figure 1d shows the prototype of the WARM system, which features a more compact size, reduced weight, and simplified design compared to RigiScan. The dual-ring approach allows the elastic sensor to simultaneously apply radial compression while providing continuous circumferential measurements.

Figure 1. Wearable Adaptive Rigidity Monitoring (WARM) System.

Design, Optimization, and Characterization of the Elastic Dual-Ring Sensor.

The elastic dual-ring sensor’s design, optimization, and characterization are crucial for its functionality in monitoring penile rigidity.

**Design and Layout**

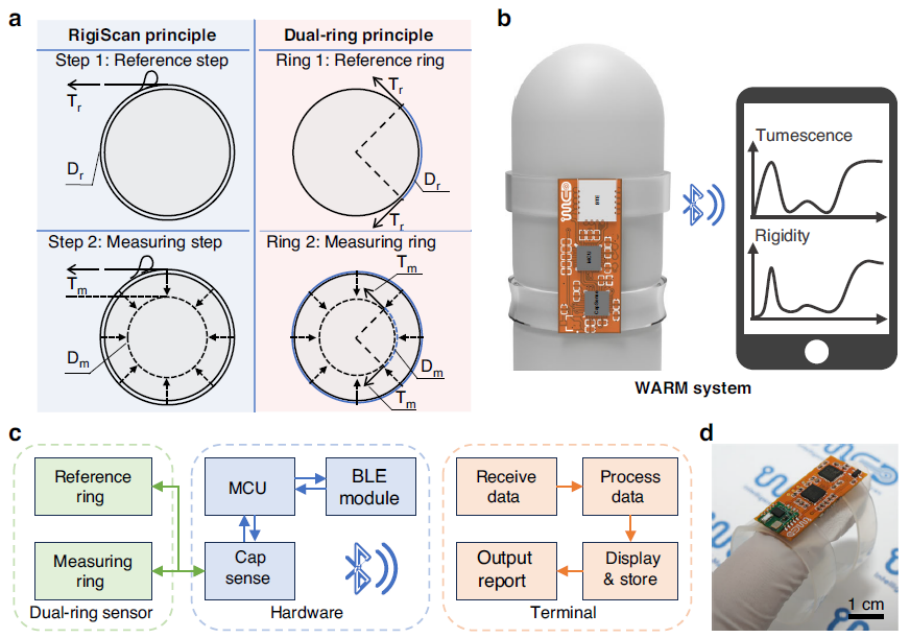

Figure 2a illustrates the planar layout of the elastic dual-ring sensor, consisting of a reference ring and a measurement ring, both based on the principle of parallel plate capacitance for strain measurement. The parallel plate sensing architecture has demonstrated high mechanical and electrical stability in continuous measurements. It is designed as a seven-layer assembly, with all layers made from highly elastic polymer materials, ensuring that the conductive layers are always separated by adjacent insulating layers. The capacitance between the conductive layers in the measurement middle and the two outer layers is evaluated to assess penile erection and rigidity. This structural design also increases the initial capacitance and device sensitivity by doubling the capacitance overlapping area. The conductive layers can be made using high-conductivity and elastic ionic gels or commercially available stretchable conductive silver paste, while the protective and dielectric layers can be made from readily available silicone rubber. Thanks to the fully flexible design, the overall structure of the sensor can withstand bending and stretching without mechanical failure (Figure 2b).

**Optimization of Geometric Parameters**

Identifying the optimal geometric parameters for the dual-ring sensor, including the thickness of the dielectric layer and the width of the electrode layers, is essential to meet the specific mechanical and electrical requirements of the design principles. Additionally, selecting suitable materials for each layer is critical. After evaluation, the authors chose a dielectric layer thickness of 200 micrometers. This thickness provides an optimal balance between sensitivity and reliability, as shown in Figure 2c, with sensitivities and initial capacitances of 95.86 pF and 1.26 pF/mm, respectively. To achieve the required precision in measuring penile circumference, the sensor must exhibit significant and stable capacitance changes under 0.1 mm deformation, corresponding to approximately 0.1% strain of the sensor. As shown in Figure 2d, samples with electrode widths of 5 mm and 7 mm exhibited stable capacitance increases of 0.172 pF and 0.258 pF under 0.1 mm deformation.

**Material Selection**

Once the geometric dimensions of the sensor were determined, it was essential to select appropriate materials to ensure that the mechanical performance meets the design requirements. The authors prepared silicone rubber samples with different elastic moduli for testing. The test results, illustrated in Figure 2e, show significant variations in the maximum tensile loads of different silicone rubber samples, ranging from 0.248 N to 2.590 N. Based on the design principles of the dual-ring sensor, Ecoflex 0020 and Dragon Skin 30 were selected as the insulating layer materials for the reference and measurement rings, respectively. Specifically, Ecoflex 0020 and Dragon Skin 30 demonstrated the minimum and maximum elastic moduli, with maximum tensile loads of 0.248 N and 2.590 N, both below the design limits. Furthermore, both ionic gel and conductive silver paste were tested as electrode layer materials, maintaining good conductivity after 1000 stretching cycles, making both materials suitable for use as electrode layers. Ionic gel is easy to prepare, cost-effective, and transparent, while conductive silver paste has lower resistance. With these material selections for the insulating and electrode layers, the dual-ring sensor met the design requirements in terms of mechanical performance, wear comfort, and conductivity.

**Characterization and Performance Evaluation**

After optimization, the dual-ring sensor was manufactured and characterized to assess its mechanical and electrical performance. Figure 2b displays an optical image of the sensor made with ionic gel and conductive silver paste. Figure 2f shows the capacitance-circumferential displacement and tension-circumferential displacement responses of the reference and measurement rings. Even under the designed maximum circumferential displacement of 37 mm, the maximum tensile forces observed for the reference and measurement rings were 0.365 N and 2.528 N, respectively, lower than RigiScan’s 1.11 N and 2.78 N. This reduction in measurement load minimizes interference with erections. Additionally, the adaptive load of the dual-ring sensor is more conducive to continuous and discreet monitoring of penile rigidity and erection.

Figure 2g illustrates the capacitance and tension recordings of the sensor using the measurement ring under stepwise changes of 1 mm deformation. The results indicate that the sensor’s capacitance and tensile load show significant changes with each small deformation and remain stable over the specified duration. In Figure 2h, the initial capacitance values of the measurement rings for five volunteers in non-contact and contact states are compared. The initial capacitance values show minimal differences (less than 0.33 pF), indicating that parasitic capacitance changes caused by different patients do not significantly affect the sensor’s actual measurements.

Through tensile cycling tests on both rings, the repeatability of the elastic dual-ring sensor was evaluated. Figure 2i demonstrates consistent mechanical and electrical performance for both the measurement and reference rings, showing no significant baseline drift after 1000 cycles.

**Figure 2. Design and Characterization of the Dual-Ring Sensor.**

**Feasibility Testing of the WARM System and Assessment of Penile Erection**

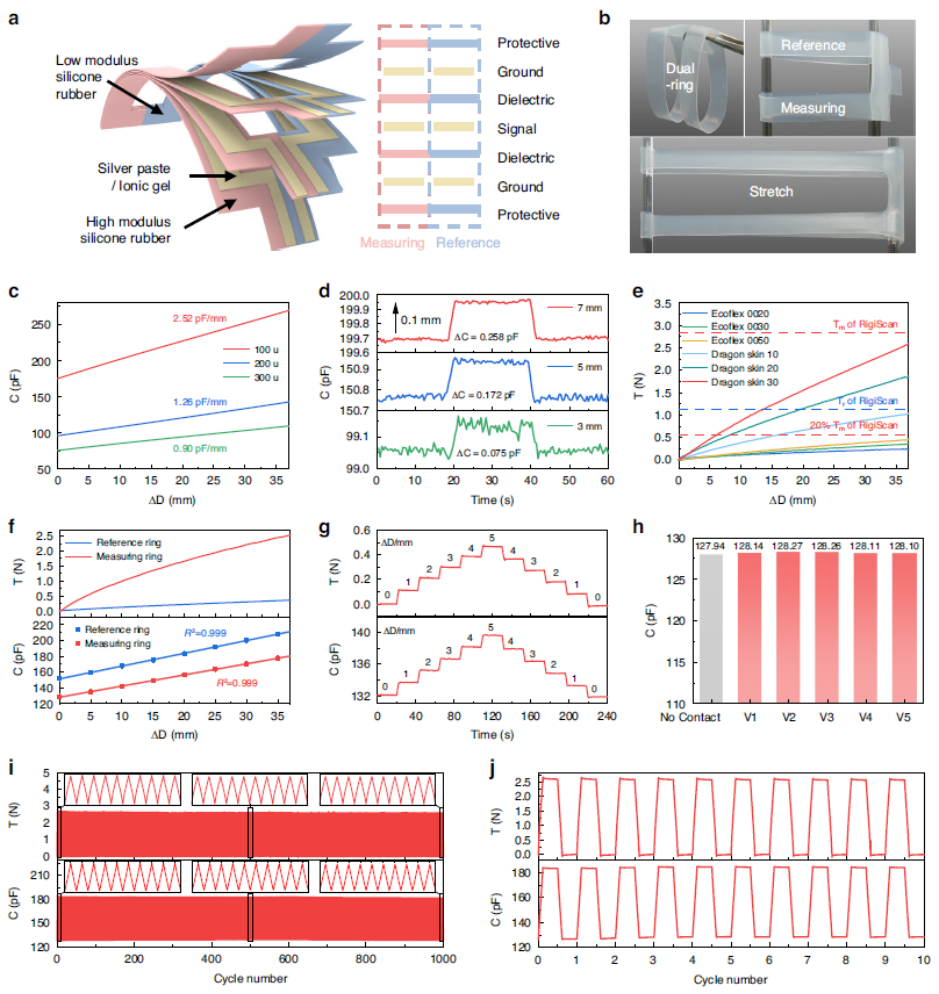

The authors developed a penile erection simulator to effectively characterize the WARM system. This simulator allows for stable and programmable adjustments of the hardness and erection of an expandable penile model, providing a standardized testing platform to evaluate the WARM system. Figure 3a shows the simulator, which includes an expandable penile model, a flow controller for indirectly adjusting the model’s hardness and circumference, and a computer equipped with corresponding control software. The penile model is a commercial hollow cylindrical structure made of elastic silicone, reflecting the physiological characteristics of penile hardness and erection as internal pressure within the corpus cavernosum changes. By adjusting its internal pressure, the model’s hardness and erection can be flexibly controlled. After connecting the pressure control unit (i.e., the flow controller), precise adjustments of the model’s hardness and erection can be programmed via the computer.

Figure 3c compares the hardness measurement results obtained from the WARM system and RigiScan on the penile model under varying internal pressures. RigiScan demonstrates poorer continuous monitoring capabilities of erections, whereas the WARM system, due to the adaptive tensile load applied by the elastic dual-ring sensor, maintains a tensile load of less than 1 Newton for hardness measurement when the model’s internal pressure is below 20 mmHg. This adaptability allows the WARM system to continuously monitor penile hardness in a patient-friendly manner without requiring full erection. The linear regression analysis of the hardness measurement results from both systems in Figure 3d shows a high level of consistency, with a correlation coefficient of 0.98. This is attributed to both the WARM system and RigiScan employing the same definition and calculation formula for radial hardness. However, their measurement principles differ: the WARM system uses elastic dual-ring measurement, while RigiScan utilizes a traditional single-step force-displacement process.

To simulate the penile erection-detumescence process during actual erection monitoring, the penile model underwent multiple inflation and deflation cycles of varying durations. Both RigiScan and the WARM system simultaneously monitored this process, with results shown in Figure 3e.

Figure 3. Feasibility Testing of the WARM System.

Volunteer Clinical Testing

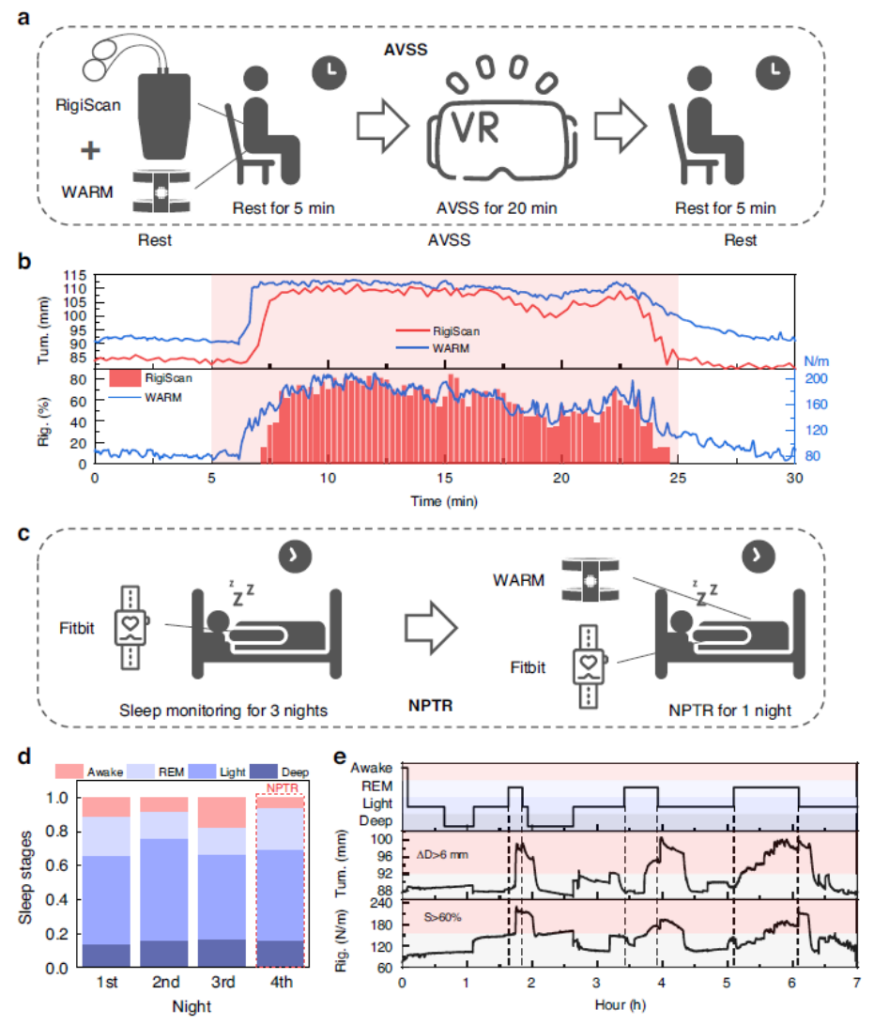

To further evaluate the clinical utility of the WARM system in monitoring erections and diagnosing erectile dysfunction (ED), the authors recruited two volunteers for the AVSS and NPTR tests. Currently, the AVSS and NPTR tests are the two main diagnostic methods for distinguishing between psychogenic and organic ED due to their non-invasive and objective nature. The results of the AVSS test are shown in Figure 4a. It can be observed that after 2 minutes of audiovisual stimulation, there was a significant increase in the erection and rigidity of the penis, indicating that an erection occurred. This erection lasted until the 22.5-minute mark, after which there was a gradual decline in both erection and rigidity, signaling the end of the erection. Comparative analysis showed that the WARM system provided superior real-time tracking of penile erection states, offering more precise circumferential assessments and high-precision rigidity measurements than the RigiScan system.

Nocturnal penile erections are a normal physiological phenomenon that typically occur during rapid eye movement (REM) sleep. To confirm the WARM system’s ability to minimize interference with sleep and nocturnal erections, the second volunteer initially wore a Fitbit for monitoring during three nights of sleep. On the fourth night, he was instructed to wear both the Fitbit and the WARM system for a combined NPTR-sleep assessment (Figure 4c). The Fitbit is a commonly used wearable sleep monitor in medical research, providing detection of sleep stages. As shown in Figure 4d, the data indicated that using the WARM system did not affect sleep quality, as there was no observed reduction in deep sleep or REM sleep duration, and no increase in wakefulness duration. Figure 4e provides a detailed analysis of sleep data and NPTR results, highlighting areas where the penile circumference increased by more than 6 mm or rigidity exceeded 60%. The comparative results validated the reliability of the WARM system in monitoring NPTR. During the seven-hour NPTR monitoring period, the WARM system demonstrated high fidelity and precision, with minimal interference with erections, thereby enhancing its clinical value in diagnosing ED.

**Figure 4. Volunteer Testing of Continuous Penile Erection Assessment Using the WARM System.**

-

Product on sale

Cute animal bear sex dolls – 92cmOriginal price was: $3,400.00.$1,599.00Current price is: $1,599.00.

Cute animal bear sex dolls – 92cmOriginal price was: $3,400.00.$1,599.00Current price is: $1,599.00. -

Product on sale

165CM F Cup Anime Tentacle Sex DollOriginal price was: $3,400.00.$1,999.00Current price is: $1,999.00.

165CM F Cup Anime Tentacle Sex DollOriginal price was: $3,400.00.$1,999.00Current price is: $1,999.00. -

Product on sale

163CM F Cup redhead succubus sex dollOriginal price was: $3,299.00.$1,999.00Current price is: $1,999.00.

163CM F Cup redhead succubus sex dollOriginal price was: $3,299.00.$1,999.00Current price is: $1,999.00. -

Product on sale

Full Silicone Cow-Headed Sex DollOriginal price was: $5,400.00.$2,199.00Current price is: $2,199.00.

Full Silicone Cow-Headed Sex DollOriginal price was: $5,400.00.$2,199.00Current price is: $2,199.00. -

Product on sale

90cm Centaur Horse Sex DollOriginal price was: $1,599.00.$999.99Current price is: $999.99.

90cm Centaur Horse Sex DollOriginal price was: $1,599.00.$999.99Current price is: $999.99.

Summary

This study developed a wearable adaptive rigidity monitoring (WARM) system capable of continuously monitoring penile rigidity and erection for clinical diagnosis of erectile dysfunction (ED). Specifically, the authors introduced a differential elastic measurement principle using a dual-ring method to replace the traditional two-step force-displacement process. This approach allows for the assessment of penile erection using a specially designed elastic dual-ring sensor, addressing challenges related to measurement reliability and patient compliance associated with mechanical moving parts. The dual-ring sensor consists of two strain-sensing rings with different elastic moduli, providing high resolution (0.1%), robust mechanical and electrical stability (sustaining over 1,000 cycles), and strong anti-interference capability. An integrated flexible printed circuit (FPC) collects and processes sensor signals in real-time and transmits them via Bluetooth to a terminal for ED assessment. To validate the reliability of the WARM system, the authors conducted experiments on penile models and human subjects, performing a detailed comparison with RigiScan. The study found that the WARM system proficiently monitors penile rigidity and erection, achieving accuracy comparable to standard clinical devices (R² > 0.98) while ensuring minimal interference with the erection process. This system provides a fully wearable, integrated solution for continuous, accurate, and patient-friendly measurement of penile rigidity and erection, potentially yielding more reliable and convenient results in the clinical diagnosis of ED.